Why 5S?

Why is the 5S methodology important?

By Andy Pritchard | November 9, 2022 | 2 minute read.

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey. The first steps are simple and build on the success of previous ones with the goal of gradual culture change towards lean manufacturing best practices.

For example, launching a plant wide “Sort” day at your facility is an easy win. You will remove clutter, institute proper storage of materials and tools, and can take “before and after” photos that visually document the improvements you’ve made. This impressive documentation will align the team around the benefits of 5S and help with buy-in for next steps.

If you are uncertain whether 5S is right for your facility ask yourself and your team the following questions:

- Do people in your workplace struggle to locate documents or files, whether in physical or digital format?

- Are there loose, sagging electrical cables in the workplace?

- Are there files, drawers, and cabinets that are unlabeled, or do they contain unmarked content that is hard to identify?

- Is valuable space taken up by useless items?

- Are there papers in your workplace that are not used and are gathering dust?

- Does everybody know how to keep the workplace organized and are fully aware of their roles and responsibilities?

If the answer was “yes” to one or more of these questions you may find 5S to be very beneficial to your organization.

Continue Reading

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

Overview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

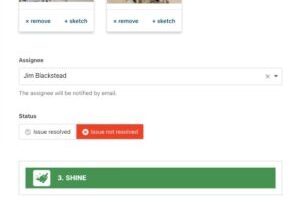

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

How to create a 5S Audit Checklist

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

How does 5S work?

The 5S methodology is built on 5 easy to remember steps that have a natural flow to them as each step builds upon the success of the last.