How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

By Andy Pritchard | February 5, 2022 | 5 minute read.

Set in Order focuses on arranging essential items in a logical and efficient manner, optimizing the workspace layout for improved accessibility, safety, and workflow.

This step ensures that everything has its designated place, streamlining processes and reducing waste.

We recommend using the “Optimization Blitz” approach to 5S implementation, where you work with small teams and execute each of the first 3 steps one per day. This approach allows for you to get the best results in the shortest amount of time.

But before we get into the Set in Order step, let’s review the 5S methodology and the first “Sort” step that will need to be completed before you begin to set workstations in order.

How to Set in Order a Workstation

The Set in Order is the “magical” step in the 5S process and it can be viewed as more of an art than a science. As a result, you may want to consider hiring the services of a lean practitioner to help you execute this crucial step.

By collaboratively assessing, redesigning, and implementing optimized layouts, frontline staff and 5S leaders create a more organized and streamlined workspace, facilitating smoother operations and improving overall productivity.

This sets the stage for the subsequent steps in the 5S methodology, emphasizing sustained orderliness and optimization within the manufacturing environment.

Here is a detailed overview of the steps involved.

1. Evaluate Current Layout

Begin by evaluating the current layout and organization of the workspace. Assess how items are currently arranged and identify any inefficiencies or safety hazards.

2. Determine Optimal Layout

Collaborate with frontline staff to determine an optimal layout. Consider factors like workflow patterns, frequency of item use, ergonomic considerations, and safety protocols.

3. Establish Item Placement Guidelines

Develop clear guidelines for item placement based on their frequency of use, workflow sequence, and ergonomic considerations. Designate specific areas for different categories of items.

What to Consider and Look For:

- Accessibility: Ensure items are easily reachable and accessible, reducing unnecessary movement or bending.

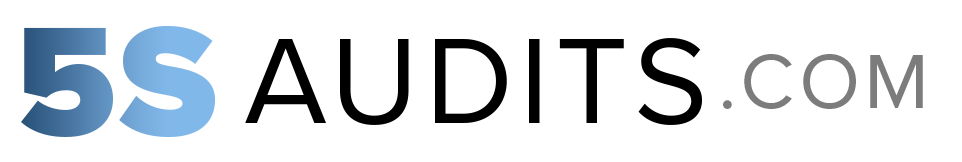

- Safety Measures: Arrange items to minimize safety hazards, keeping heavy or hazardous items stored securely and appropriately.

- Optimal Space Utilization: Maximize space utilization by organizing items efficiently, avoiding clutter and obstructions.

4. Redesign Workspace Layout

Based on the determined guidelines, rearrange the workspace layout. Ensure commonly used items are easily accessible, frequently accessed tools are within arm's reach, and less used items are stored further away.

Continue Reading

Why is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

Overview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

How to create a 5S Audit Checklist

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

How does 5S work?

The 5S methodology is built on 5 easy to remember steps that have a natural flow to them as each step builds upon the success of the last.