How to Build your 5S Audit Digitization Project Plan

By Andy Pritchard | Feb 5, 2024 | 2 minute read.

In today's fast-paced and ever-evolving business landscape, digitization is not just an advantage, it's a necessity. For companies looking to implement 5S methodologies—a cornerstone of lean management—the shift from traditional paper-based systems to digital platforms can be transformative.

Creating a comprehensive project plan, or Business Case, is a critical step in this transition. It serves as a strategic blueprint, detailing the need, goals, and anticipated benefits of digitization. More than just a document, it’s a persuasive communication tool to present to leadership, succinctly conveying how digitization aligns with broader business objectives and the tangible efficiencies it promises.

Let's delve deeper into each of the Project Plan sections to provide you with everything you need to impress senior management and get the ball rolling on your digitization project.

How to Build a 5S Audit Digitization Project Plan

Creating a project plan (or Business Case) is helpful for communicating the need, goals and benefits of digitization to leadership. The project plan also helps you elicit help from leaders within your organization.

To Build a Business Plan for 5S Digitization follow these steps:

- Align Project Goals with Organizational Objectives

- Gather Evidence & Benchmark Data

- Establishing a Baseline for Improvement

- Outline Implementation Plan

- Calculate Potential Return on Investment (ROI)

- Develop a Compelling Presentation

1. Align Project Goals with Organizational Objectives

Digitizing your 5S program is going to take resources, so you will need to compel senior leadership to provide them. The best path to do this is to demonstrate how 5S digitization aligns with the current corporate objectives.

The specific objectives of your 5S digitization project should become clearer when you have completed this exercise. It is helpful to keep your goals crystal clear during the implementation so you do not stray off track. Goals are helpful for making decisions as you go.

Download the free 5S digitization presentation template to review example goals for your digital implementation.

2. Gather Evidence & Benchmark Data

Now that you are clear on what you want to achieve, you can begin digging deeper into your current auditing program to assess specifically how it can be improved through digitization. It is crucial to gain a deep understanding of the current 5S processes in place, especially relating to the pain points that can be solved through digitization.

Review Auditing Program

Begin by reviewing your current documentation, audit frequency and consistency and the data you are capturing:

- Audit Documentation: Begin by reviewing existing 5S audit documentation. Analyze the structure, frequency, and thoroughness of audits to understand the current state of compliance and adherence to 5S principles.

- Schedule Frequency and Consistency: Assess the frequency of 5S audits and their consistency across different areas of the organization. Identify if there are variations in audit practices that may lead to discrepancies in compliance levels.

- Audit Data: Does the information captured from audits contain enough information to spot trends and insights? Are you capturing data around audit completion time, non-compliance rates, and corrective action turnaround times. What is the data not providing that you need to be successful?

Engage with Key Stakeholders

Once you have reviewed the program documentation, schedule and data, you should engage with key stakeholders, including auditors, employees, and department heads, to gather qualitative insights. Explore their perspectives on the effectiveness of current auditing practices and any challenges they face. Some practical ways to identify pain points and inefficiencies that can be addressed with digitization include:

- Employee Feedback Sessions: Conduct feedback sessions with employees involved in or affected by 5S audits. Collect input on pain points, bottlenecks, and inefficiencies they encounter during the auditing process.

- Analysis of Non-Compliance Trends: Examine historical data on non-compliance incidents. Identify recurring issues or trends that may indicate systemic inefficiencies in the current 5S auditing practices.

- Surveying Auditors: Survey auditors to understand their experiences and challenges. Identify any roadblocks they encounter in conducting effective audits, documenting findings, and implementing corrective actions.

SWOT Analysis for Current 5S Auditing Practices

Armed with information from your interviews, you may want to consider presenting this information to senior leadership through a SWOT (Strength, Weaknesses, Opportunities, Threats) analysis. This analysis provides a holistic view of the internal and external factors influencing the effectiveness of the auditing processes.

For an example of a SWOT analysis, you can download the 5S digitization project plan template here: http://weeverapps.com/free/5s-digitization-presentation-template/

3. Establishing a Baseline for Improvement

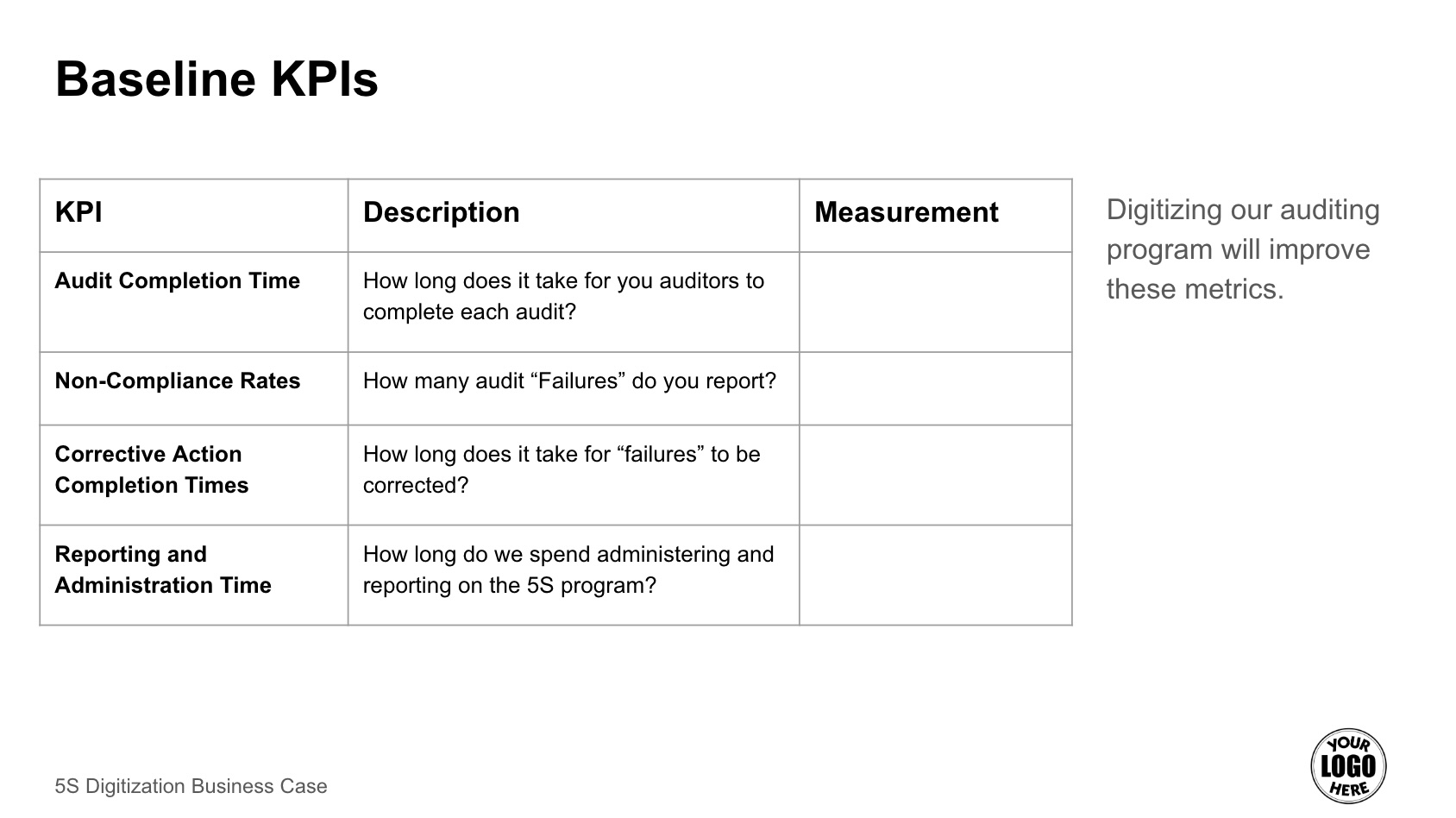

Now that you understand the goals and pain points, you need to capture quantitative baseline metrics that you can use to establish a return on investment (ROI) for digitization. This process involves evaluating key performance indicators (KPIs) to understand the current state of the auditing system.

Metrics such as audit completion time, non-compliance rates, and corrective action turnaround times play a pivotal role in providing insights into the efficiency and effectiveness of existing practices.

In paper-based systems, auditors manually compile information from completed audits, creating reports by hand. Administrative tasks, such as updating communication boards, are also time-consuming and rely on manual effort.

Download the presentation template for access to more information about Baseline KPI measurement.

4. Outline Implementation Plan

Now that you have assessed your goals, the specific pain points you want to address, and the baseline quantitative metrics you are looking to improve, it is time to outline the phases and steps in your implementation plan.

This guide includes a whole section on implementation best practices that you can review later in this guide. For the Project Plan, however, it is useful to present an overview of the phases involved in the project.This can include the goals for each phase, resource requirements and estimated timelines.

Below is an example of an Implementation Plan that you can use to create your own. Each company operates differently and at their own pace, however, following this process is the best way we have witnessed to deliver a successful implementation.

These phases and timelines are outlined in our presentation template, which you can download here: http://weeverapps.com/free/5s-digitization-presentation-template/

5. Calculate Potential Return on Investment (ROI)

Understanding a potential ROI is a great way to show senior management that you have thought through the costs and benefits of the program and you are interested in the financial success of the organization.

To calculate the return on investment for digitizing your 5S audits, you will need to understand the costs and the hard returns associated with the program. Once you have a handle on these figures you can easily find ROI %, which is the net annualized benefit divided by the total annualized costs multiplied by 100, or simply:

ROI (%) = ((Total Benefits - Total Costs) / Total Costs) x 100

What are the potential costs?

Cost estimates can vary widely depending on factors such as the chosen software, the organization's size, complexity, and specific requirements. Here is a list of estimated costs you may want to include in your Project Plan.

- Software Licensing Fees: Costs associated with purchasing licenses for the 5S audit digitization software or platform. Licensing fees can vary widely depending on the chosen software's features and scalability.

- Implementation and Setup: Expenses related to the initial setup and configuration of the digitization platform, including data migration, customization, and integration with existing systems if necessary. Typically, this cost is calculated based on the scope of customization and the complexity of the implementation project. It can be estimated through discussions with software vendors or implementation partners. This can vary widely but may range from $20,000 to $100,000 or more for a comprehensive implementation.

- Training and User Adoption: Costs associated with training employees and auditors on how to use the digital audit platform effectively. This includes training materials, instructor fees, and productivity losses during training. Estimate the number of users who require training and the duration of training sessions. Multiply this by the cost per user or per training session. Training costs can range from $50 to $500 per user, depending on the complexity of training requirements.

- Maintenance and Support: Ongoing expenses for software updates, technical support, and maintenance of the digitization platform. Typically, maintenance and support costs are a percentage of the initial software licensing fees. It can be estimated by considering the vendor's support pricing model. This may be around 15-20% of the annual licensing fees, so if the licensing fee is $20,000, the annual maintenance and support cost could be $3,000 to $4,000.

- Hardware and Infrastructure: Costs related to hardware and infrastructure upgrades or enhancements required to support the digital audit platform, such as networking and wi-fi improvements or tablets and mobile devices. Calculate the costs associated with any necessary hardware upgrades or additional equipment purchases. This can vary significantly based on the existing infrastructure and requirements but may range from a few thousand to tens of thousands of dollars.

What are the hard and soft benefits of 5S digitization?

Now it is time to estimate the benefits of 5S digitization to complete your ROI calculation. Some benefits will translate easily to dollars. These are considered “Hard ROI” benefits. Other benefits are not as easy to convert into dollars directly but it is easy to understand how they positively affect the organization. These are “Soft ROI benefits”.

You can get into trouble trying to convert these to hard dollar benefits, so we recommend separating the 2 benefits and simply listing soft benefits but not including them in your equation.

Hard ROI Benefits

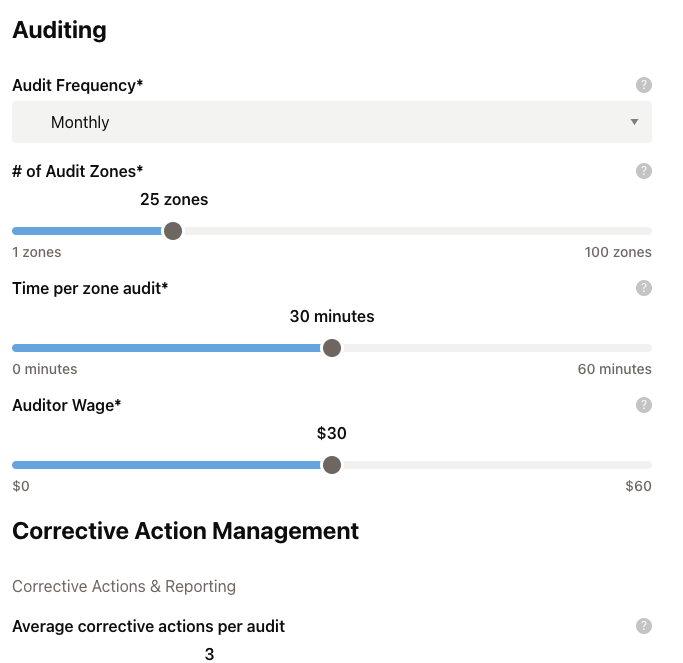

- Time Savings: The reduction in the time required to conduct and manage 5S audits due to streamlined processes and real-time data access. Calculate the average time spent on manual audits before digitization and compare it to the time spent on digital audits. Multiply the time saved by the hourly wage of auditors. Potentially thousands of hours saved annually, resulting in significant cost savings.

- Reduced Document Management Costs: The elimination or significant reduction of costs associated with printing, storing, and managing paper-based audit forms and documents. Calculate the annual expenses related to paper, printing, storage, and document management before digitization. Savings could range from several thousand to tens of thousands of dollars per year.

Soft ROI Benefits

- Increased Efficiency: Improved operational efficiency and productivity resulting from quicker identification and resolution of issues identified during audits.

- Estimate the percentage increase in efficiency due to digitization and apply it to relevant operational costs.

- Efficiency gains can lead to substantial savings in operational costs, depending on the extent of improvement.

- Improved Compliance: Enhanced adherence to 5S principles and regulatory requirements, leading to fewer compliance issues and potential penalties.

- Assess historical compliance issues and estimate the reduction in non-compliance incidents after digitization.

- The savings can be significant, potentially avoiding penalties and fines.

- Enhanced Data Analysis: The ability to analyze audit data in real-time, identify trends, and make data-driven decisions for continuous improvement.

- Assess the impact of data-driven decision-making on operational improvements and potential cost savings.

- This benefit can result in significant cost reductions by optimizing processes and resource allocation.

- Employee Engagement and Satisfaction: Increased employee engagement, satisfaction, and retention due to user-friendly digital tools that simplify the audit process.

- Consider the potential impact of improved employee morale on productivity and turnover rates.

- While harder to quantify, improved employee engagement can have long-term financial benefits.

To help you in this process, we have a handy ROI calculator you can use to assess and monetize time savings for auditing, corrective actions and administration. You can toggle the inputs to suit your estimates and email yourself the results. https://weeverapps.com/calculator/5s-audit-digitization-roi/

6. Develop a Compelling Presentation

After you have completed the above steps you will have an excellent understanding of what you want to achieve, how you are planning to achieve it, and how your company will benefit from the investment of time and money to make it happen.

Now it is time to present your findings to senior management to gain alignment and access to the resources you need.

To help you with this endeavour, we have developed a presentation template you can use. It is available here: http://weeverapps.com/free/5s-digitization-presentation-template/

The presentation template outlines:

- Goals of the program

- Pain points to overcome

- KPIs to improve

- Implementation plan

- Expected ROI

Continue Reading

Why is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

Overview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

How to create a 5S Audit Checklist

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.