How to create a 5S Audit Checklist

Practical guide to creating simple and powerful 5S audit checklists to ensure 5S principles are sustained and improvement opportunities are captured.

By Andy Pritchard | February 5, 2022 | 5 minute read.

If you are reading this guide, you have probably completed the workstation “Optimization” phase of 5S and you are looking for a way to “Normalize” your efficiency gains through 5S audits.

Creating efficient and rich checklists is crucial to the success of your program.

It is important to balance your need for comprehensive information to drive better strategic decisions with the need to make the audit as productive as possible.

What is a 5S Audit Checklist?

A 5S audit checklist is a structured tool used to evaluate and assess a workspace's adherence to the principles of 5S: Sort, Set in Order, Shine, Standardize, and Sustain. It serves as a comprehensive guide for auditors to systematically inspect various areas, processes, or departments within an organization to ensure they align with 5S standards and practices.

The checklist is typically organized into sections corresponding to each of the 5S principles, with specific items or criteria listed under each section. These items detail observable standards or behaviors that demonstrate compliance or non-compliance with the respective 5S principle.

- Sort - Assess the presence of unnecessary items or clear identification of essential tools

- Set in Order - Evaluate the logical arrangement of items and whether there are designated places for everything

- Shine - Criteria for workspace cleanliness and adherence to regular cleaning schedules

- Standardize - Assess whether standardized procedures are in place for maintaining organization and cleanliness.

- Sustain - Indicators of a culture that promotes continuous improvement and adherence to established 5S practices over time.

The checklist acts as a roadmap for auditors during assessments, guiding them through specific criteria to evaluate, document findings, and identify areas for improvement or commendation. It aids in ensuring consistency, objectivity, and thoroughness in evaluating the workspace against 5S principles.

How to create your 5S audit checklists

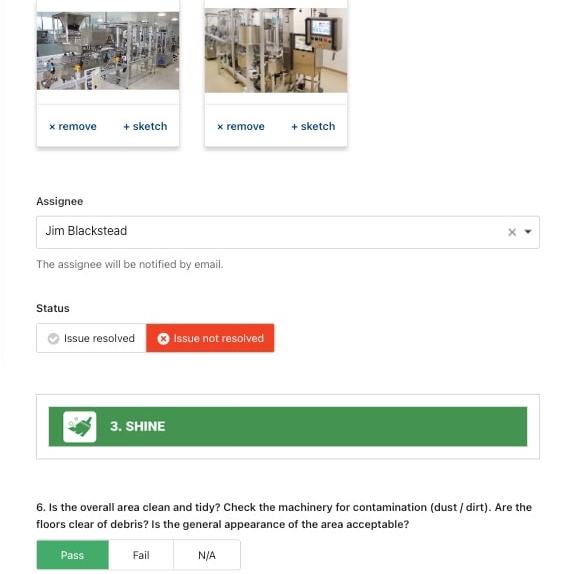

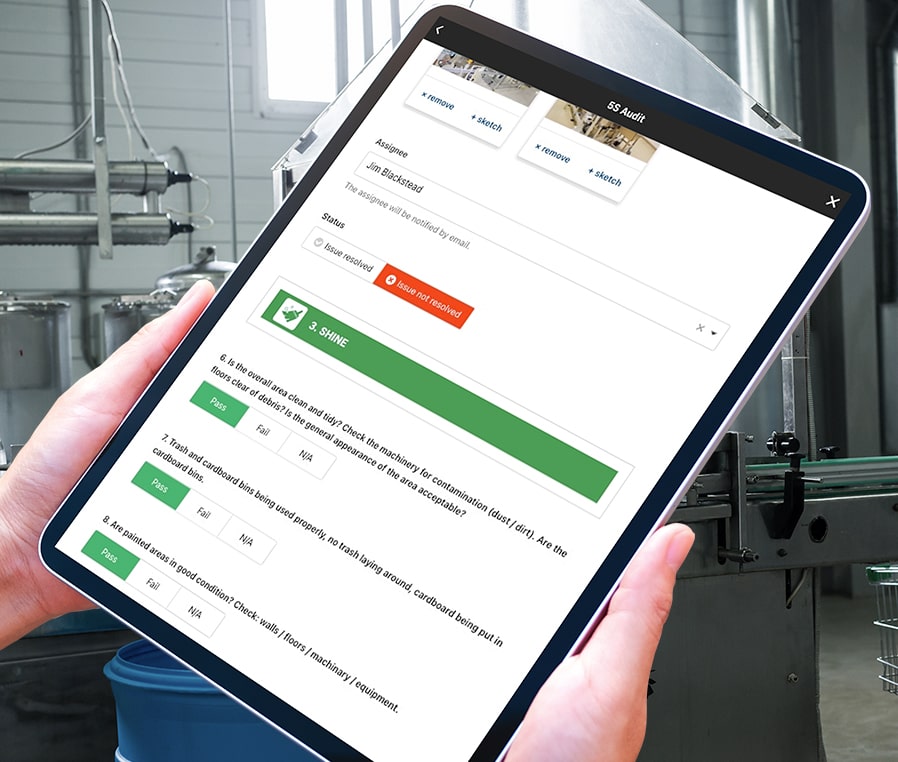

Once your 5S audit criteria for each workstation, you can move forward and build your checklists. Audit checklist forms can be constructed in many different ways. Some find value in a grading system, whereas others want to assess more “binary” information, i.e. pass/fail. The grading system provides more context and the binary “pass/fail” system is easier to understand and more efficient to review.

In our experience, the best practice is to ask simple “pass/fail” questions, where only “failures” request additional information. The result of this is a highly efficient experience where rich data is captured when required.

Checklists should provide clear instructions to the auditor, especially when asking qualitative questions. What does “pass” mean in this case? What does “fail” mean?

Here is a comprehensive list of best practices you can use to create your 5S Audit Checklists:

1. Be Specific and Objective

Ensure that the checklist items are specific, measurable, and objective. Avoid vague or ambiguous criteria that may lead to differing interpretations during audits.

2. Tailor to Each Unique Workspace

Customize the checklist to suit the unique needs and functions of different work areas or departments. What may be essential in one area might differ in another based on the nature of the work conducted.

3. Include Visual Aids or References

Incorporate visual aids, photographs, or reference materials where applicable to illustrate the expected standards. Visual references help auditors better understand and assess criteria.

4. Provide Clear Instructions

Include clear instructions or guidelines for auditors on how to conduct assessments, what to look for, and how to document findings. This ensures consistency in audit execution.

5. Consider Compliance Requirements

If there are specific compliance standards or regulations relevant to the workspace, ensure that the checklist incorporates these requirements for comprehensive assessments.

6. Quantitative and Qualitative Measures

Incorporate both quantitative and qualitative measures into the criteria. Quantitative measures might include specific counts (e.g., number of items in a workspace), while qualitative measures could involve visual inspections for cleanliness or organization.

7. Review and Validation

Review the checklist for completeness and accuracy. Validate the checklist by testing it in a real workspace environment to ensure its effectiveness before formal implementation.

8. Update and Refine as you go

Regularly update and refine the checklist based on feedback, changing organizational needs, or improvements identified during audits. The checklist should evolve to remain relevant and effective.

Continue Reading

Why is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

Overview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

How does 5S work?

The 5S methodology is built on 5 easy to remember steps that have a natural flow to them as each step builds upon the success of the last.