How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

By Andy Pritchard | February 5, 2022 | 5 minute read.

For manufacturing facilities, precision, consistency, and efficiency reign supreme. The 5S methodology stands as a beacon, guiding industries toward optimized operations.

Among its fundamental steps, standardization holds a pivotal role in ensuring uniformity, reliability, and continuous improvement. Let's explore how standardization fuels the essence of 5S within manufacturing environments.

5S is a methodology deeply rooted in Japanese practices, emphasizing the principles of workplace organization and visual management. The five steps—Sort, Set in Order, Shine, Standardize, and Sustain—form a comprehensive system to enhance productivity, safety, and quality.

Standardization, the fourth step, plays a crucial role by establishing and maintaining uniformity in the application of the 5S methodology across workstations. It ensures that processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability.

Standardization Step-by-Step Guide

The success of standardization lies in its integration into the organizational DNA, where it becomes second nature to all involved—a true testament to the power of the 5S methodology in manufacturing. Follow these steps to standardize the 5S methodology:

1. Define Clear Standards

- Establish comprehensive guidelines detailing how each 5S step should be executed.

- Specify expectations for organization, cleanliness, safety protocols, and visual cues.

2. Develop Standardization Procedures

- Create step-by-step procedures for implementing each 5S step.

- Provide training and resources to ensure everyone understands and follows these procedures.

3. Implement Visual Management

- Use visual cues such as color coding, labels, and signage for clear identification of tools, materials, and designated areas.

- Visual aids should convey standardized processes and expectations.

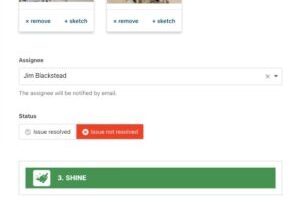

4. Regular Audits and Assessments

- Conduct frequent audits to assess adherence to standardized practices.

- Gather feedback and data to identify areas for improvement and adjust standards as necessary.

5. Documentation and Communication

- Document standardized procedures and guidelines for easy reference.

- Communicate changes or updates in standards promptly and effectively to all stakeholders.

Continue Reading

Why is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

Overview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

How to create a 5S Audit Checklist

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

How does 5S work?

The 5S methodology is built on 5 easy to remember steps that have a natural flow to them as each step builds upon the success of the last.