History of 5S

What is the history of the 5S methodology

By Andy Pritchard | November 9, 2022 | 2 minute read.

Post World War 2 Japan had an enormous impact on Lean Manufacturing theory, forging new ground on how to make plants more efficient and safe. The Toyota Motor Company and analysts like Hiroyuki Hirano helped Japanese production outpace their American counterparts who soon took note and began to implement similar measures in their own plants domestically. Prior to Japanese innovation much of the progress in North America had come from the Ford Motor Company’s moving assembly line which had reduced the time needed to assemble an automobile from 12 hours to 90 minutes.

Continue Reading

Why is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

Overview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

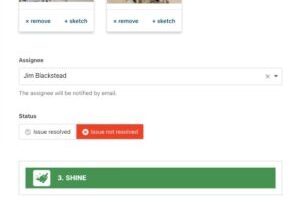

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

How to create a 5S Audit Checklist

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.