Digitization Benefits

What are the Benefits of Digitizing 5S Auditing?

By Andy Pritchard | November 9, 2022 | 2 minute read.

Positive momentum, employee buy-in, and ease of use are all very important factors when determining if your new 5S program will be successful.

Complicated manual audit forms, data entry, hard to read paper forms that are messy or incomplete, and complicated spreadsheets can doom your new 5S program to failure. Fortunately, Industry 4.0 and digitization provide us with many new tools to help make the implementation and execution of lean initiatives like 5S much easier.

With Weever your digital 5S audit forms can start for a little as $199 per month - including an insightful dashboard to make analyzing your results as simple as opening a web browser. Here are a few reasons to consider why working with Weever is the right choice for your plant:

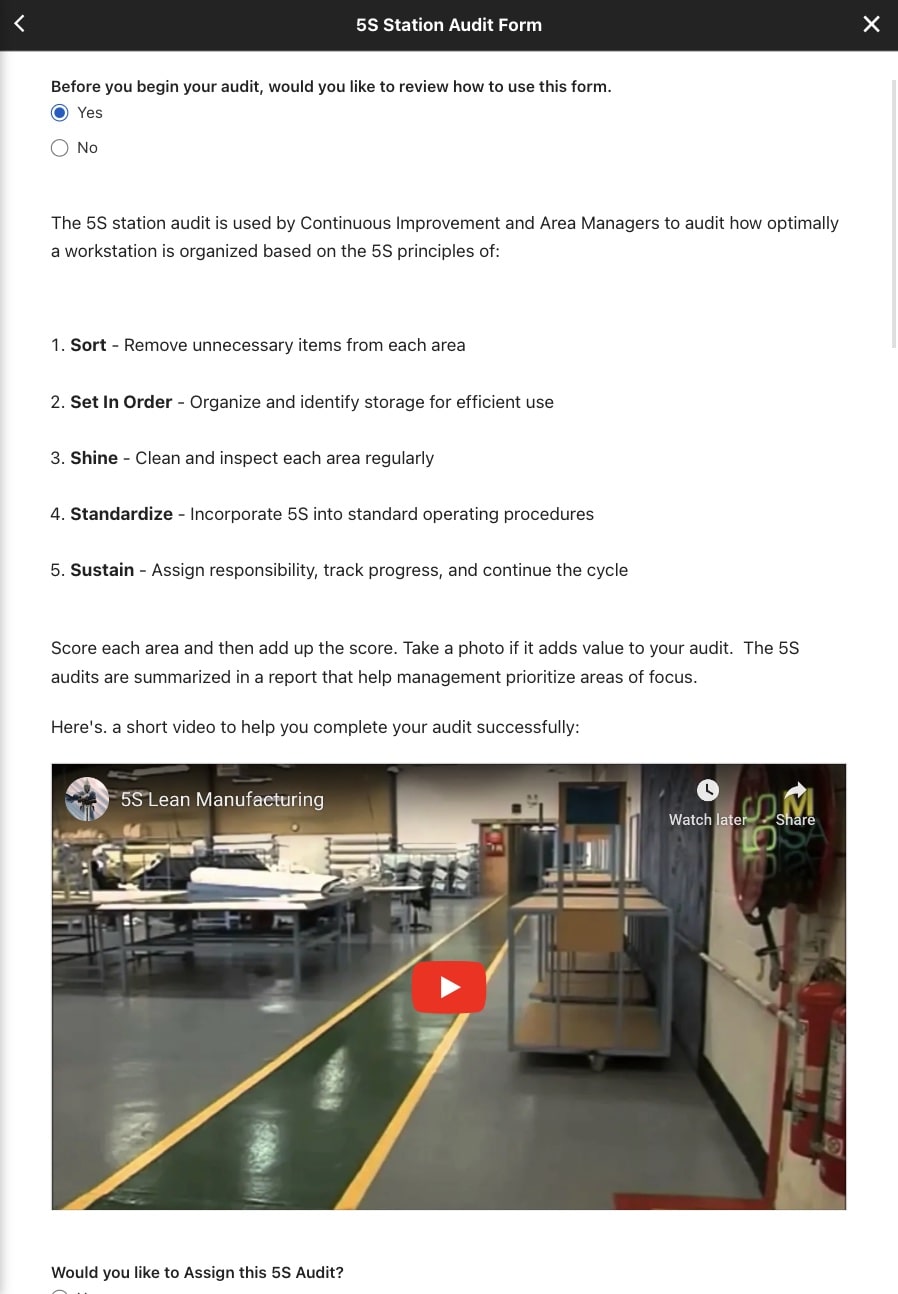

ON-DEMAND INSTRUCTIONS

Show them the way.

Give your auditors a tablet with step-by-step instructions on how to complete their 5S audits and to reduce training requirements when staff turnover. Multiple choice, dropdown menus, and conditional logic help you capture the data you need in a logical and easy-to-follow format. Forms are customizable and simple to change so they can evolve as your 5S audits do.

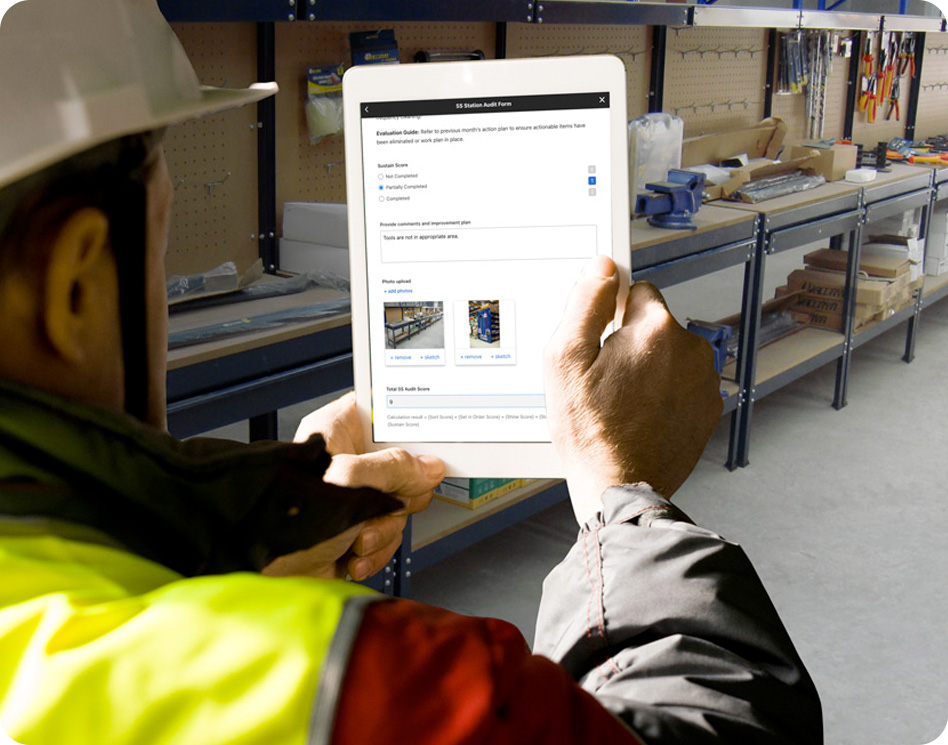

RICH DATA CAPTURE

A picture is worth a thousand words.

Take a photo with your phone or tablet that automatically populates in your audit forms. Talk-to-text allows your staff to say what they mean and capture it without the hassle of typing long or complex observations.

MOTIVATE & INSPIRE

Reward participation.

Weever Rewards allows you to automatically reward your 5S champions with points that can be redeemed in a self-managed rewards store. Broadcast the results of your 5S wins in your plant. Everybody likes seeing their name “up in lights”!

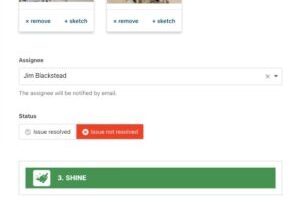

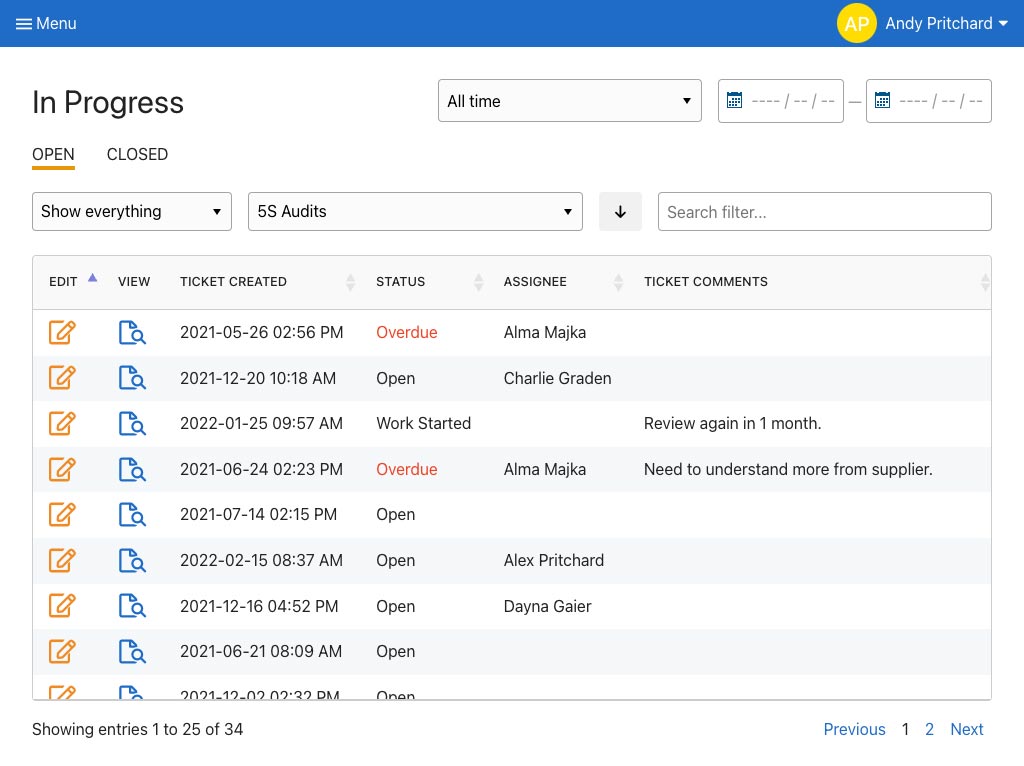

MANAGE WORKFLOWS

Automate escalation and evaluation.

Is there a follow up item to your audit that you need to assign to another stakeholder to ensure resolution? Automatically transform 5S audit results into tickets that foster easy and transparent communication and ensure they are actioned in a timely manner. Email notifications to stakeholders let them know when they’re needed. Track closing times to ensure world-class support.

AUTOMATE REPORTING

Let the software do the work.

Tallying 5S scores and entering results into spreadsheets is busywork that detracts from the productivity of your 5S committee. Over time this work may become deprioritized meaning that the data is being collected, but not analyzed. This will rob you of the opportunity to prove to your stakeholders your 5S program is having a positive impact in your plant. Software based audit forms will automatically tally scores and record results that are both intuitive and insightful.

Continue Reading

Why is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

Overview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

How to create a 5S Audit Checklist

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.