Welcome to 5SAudits.com

Everything you need to know about the 5S methodology.

5SAudits.com provides lean practitioners with access to tools and resources to help them better understand the 5S framework and how to use it to take their operational efficiency to the next level.

5S Overview

What is 5S and how does it work?

Overview of 5S Methodology

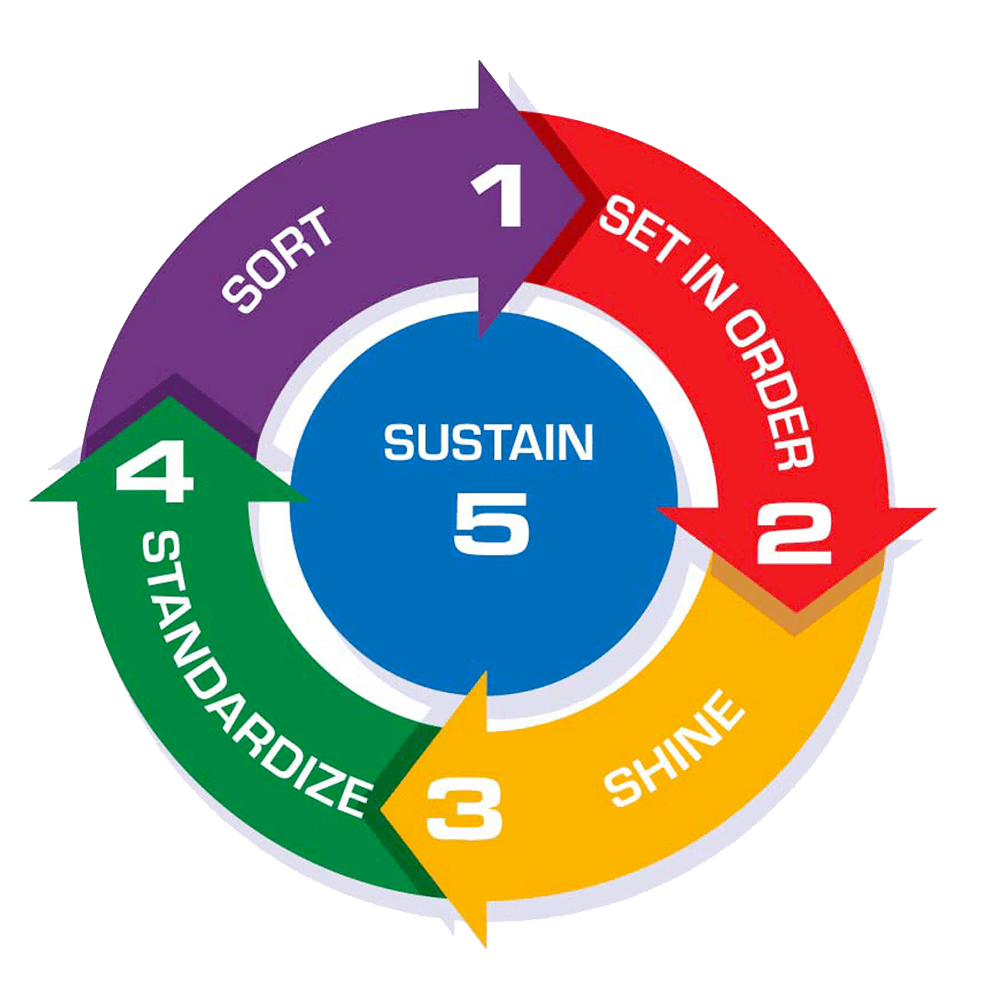

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

History of 5S

Post World War 2 Japan had an enormous impact on Lean Manufacturing theory, forging new ground on how to make plants more efficient and safe.

Why is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

The Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

How does 5S work?

The 5S methodology is built on 5 easy to remember steps that have a natural flow to them as each step builds upon the success of the last.

5S Implementation

Steps involved in implementing and sustaining a successful 5S program.

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

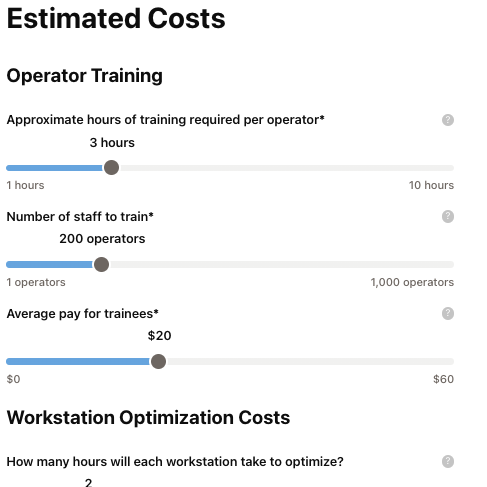

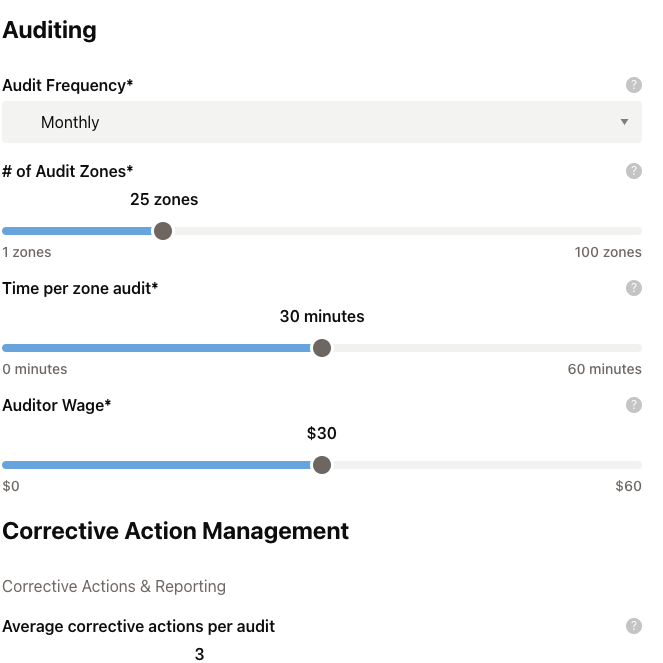

5S Implementation ROI Calculator

Interested in understanding what return on investment you could realize with a successful 5S program implementation? Try our ROI calculator

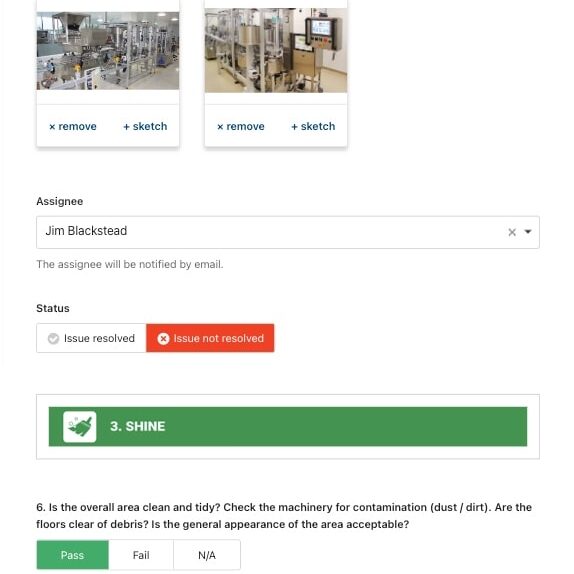

How to create a 5S Audit Checklist

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

How to Standardize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

How to Sustain with 5S Auditing

Practical guide to sustaining 5S and continuously improving workstation productivity.

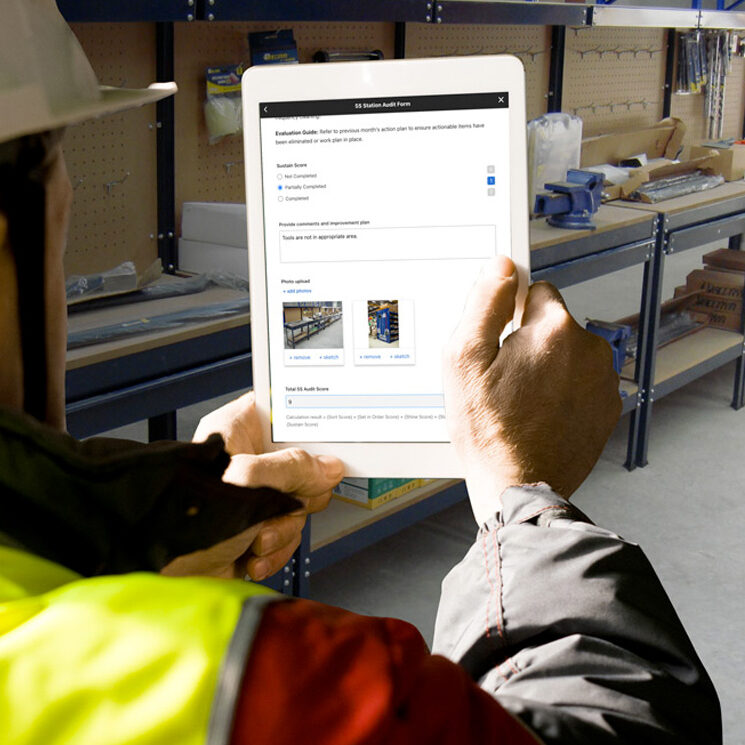

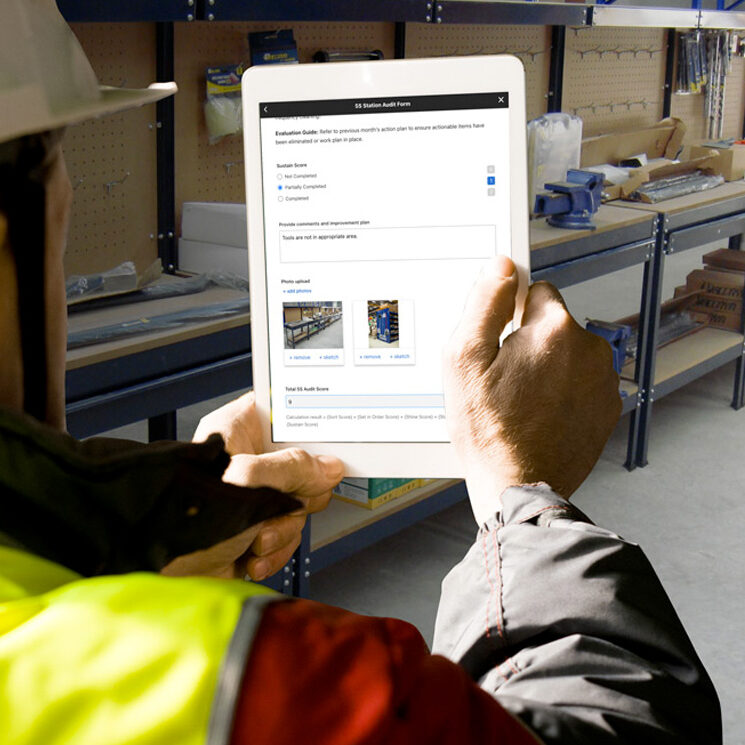

5S Digitization

How to digitally transform your 5S auditing program.

Benefits of Digitization

Positive momentum, employee buy-in, and ease of use are all very important factors when determining if your new 5S program will be successful.

5S Digitization Project Plan

Step-by-step guide to creating an airtight 5S audit digitization project plan to gain internal alignment and support from senior management.

5S Audit Digitization ROI Calculator

Interested in learning approximately how much you will save by digitizing your 5S auditing program?

Download the Ultimate Guide to

Digitizing 5S Audits

in Manufacturing and Warehouse Facilities

Everything you need to know to successfully digitize your 5S auditing program.

Download the guide to understand best practices and easy-to-follow implementation plans from our 10 years of experience helping organizations digitally transform.