Posts by Andy Pritchard

Step-by-Step Facility-wide Implementation Roadmap

The phases of implementation including the objectives, step-by-step execution strategies, resource necessities, and timeline estimations for each phase.

Read MoreBenefits of Digitization

Positive momentum, employee buy-in, and ease of use are all very important factors when determining if your new 5S program will be successful.

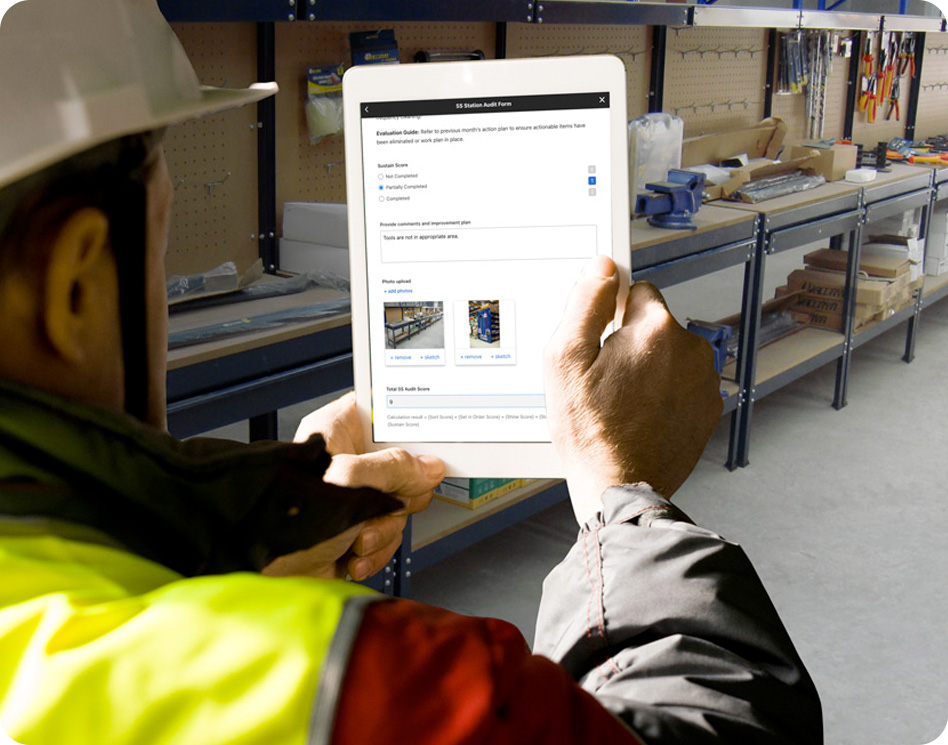

Read More5S Auditing

A crucial part of Sustain is completing regular 5S Audits.

Audits will help to maintain the gains of your 5S Action Plan to date and also find new ways to make your workstations more efficient, safe, and productive over time. Audits can be performed in a Gemba walk style format, with members of your 5S committee or management doing floor walks with a structured agenda. Most companies use a 5S audit form that will score a given workstation on how well it achieves the ideals of Sort, Set in Order, and Shine.

How does 5S work?

The 5S methodology is built on 5 easy to remember steps that have a natural flow to them as each step builds upon the success of the last.

Read MoreThe Benefits of 5S

Aside from the cultural shift towards lean manufacturing that quick 5S wins can bring for your teams, there are over 50 years of well documented benefits worth discussing.

Read MoreWhy is 5S important?

5S is often one of the first lean manufacturing processes companies implement on their continuous improvement journey.

Read MoreHistory of 5S

Post World War 2 Japan had an enormous impact on Lean Manufacturing theory, forging new ground on how to make plants more efficient and safe.

Read MoreOverview of 5S Methodology

The 5S System is a lean manufacturing tool designed to improve efficiency and productivity in your plant by making it more organized and efficient.

Read More